Vital Materials Equipment

At Vital Materials, we offer a comprehensive portfolio of advanced thin film coating systems engineered for precision, performance, and flexibility. From R&D environments to high-volume production lines, our equipment supports a broad range of applications, including vacuum coating, sputtering, vapor deposition, and PECVD, across diverse substrate types such as wafers, lenses, flexible films, and complex geometries. Whether you're optimizing semiconductor manufacturing, developing interference optics, or scaling pilot production, our modular and inline solutions deliver the configurability and reliability needed to meet the demands of next-generation technologies.

For more information or to discuss custom configurations, contact our team at sales@vitalchemusa.com.

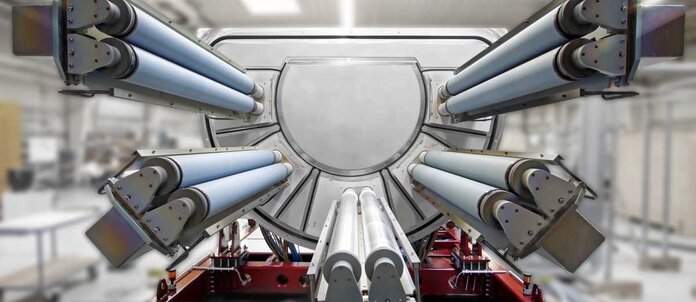

Freely Configurable Cluster Systems

Versatile thin film coating systems designed to handle a wide range of substrates, from plates, disks, and wafers to highly delicate components like needles and pins. Whether it’s layer deposition or pre- and post-treatment, the modular STAR series can be tailored to meet the demands of R&D, pilot production, and small to medium-scale

manufacturing.

- Proven, flexible modular concept with central

- Trasfer arm handling

- Diverse technological processess

- Handling as a single substrate or in a carrier

- Manual loading or automatic handling from the magazine

- Clean room connection is possible

- Inline Vacuum Coating Systems with PVD and Plasma CVD Technology

- Thin film coating systems for coating plates, wafers, wafers for R&D, as well as pilot or high-volume series production.

- Horizontal inline systems

- Vertical inline systems

- Carrierless and with carriers

- With and without carrier return systems

- With fully automatic substrate on request

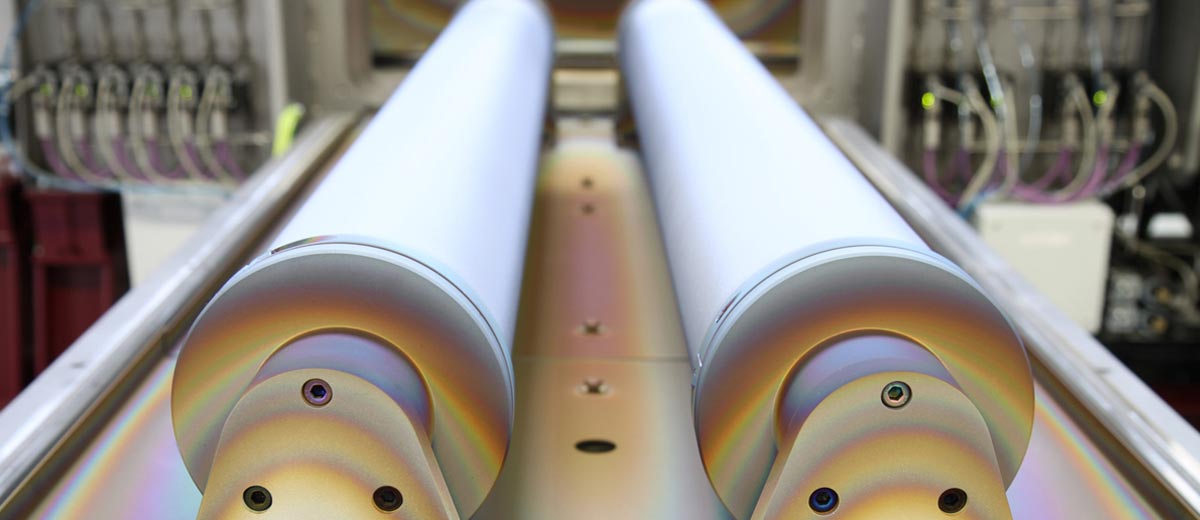

- Sputtering, Vapor Deposition, PEVCD Systems for Flexible Substrates

- Thin film coating systems for coating flexible substrates for R&D and pilot or high-volume series production.

- For coating plastic and metal films

- Flexible substrates up to 1.90m width

- With or without airlock systems

- With or without front roller contact

- Precision Sputter Coating Systems for Interference Optics Applications

- Thin film coating systems for the development and production of precision optics.

- For coating filter glasses, lenses, mirrors, and much more

- For coating thin glasses and thick glass

- With magazine airlock

- Sputter-up process for particle minimization

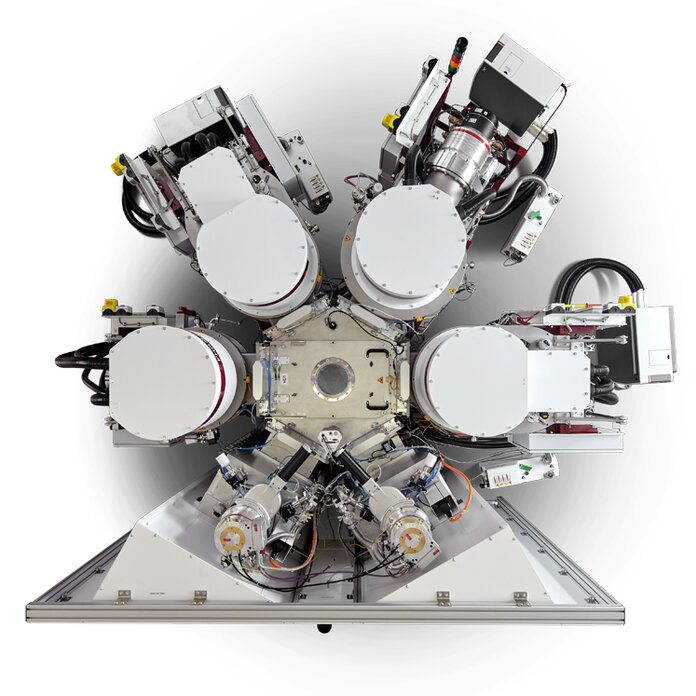

- Magnetron Sputtering Systems with Special Drum Concept for Small Substrates

- Thin film coating systems for coating plates, disks, wafers, pins and needles for R&D Production.

- Single chamber systems

- Systems with lock chamber

- With and without sub-rotation

- With clean room connection