Featured Technologies

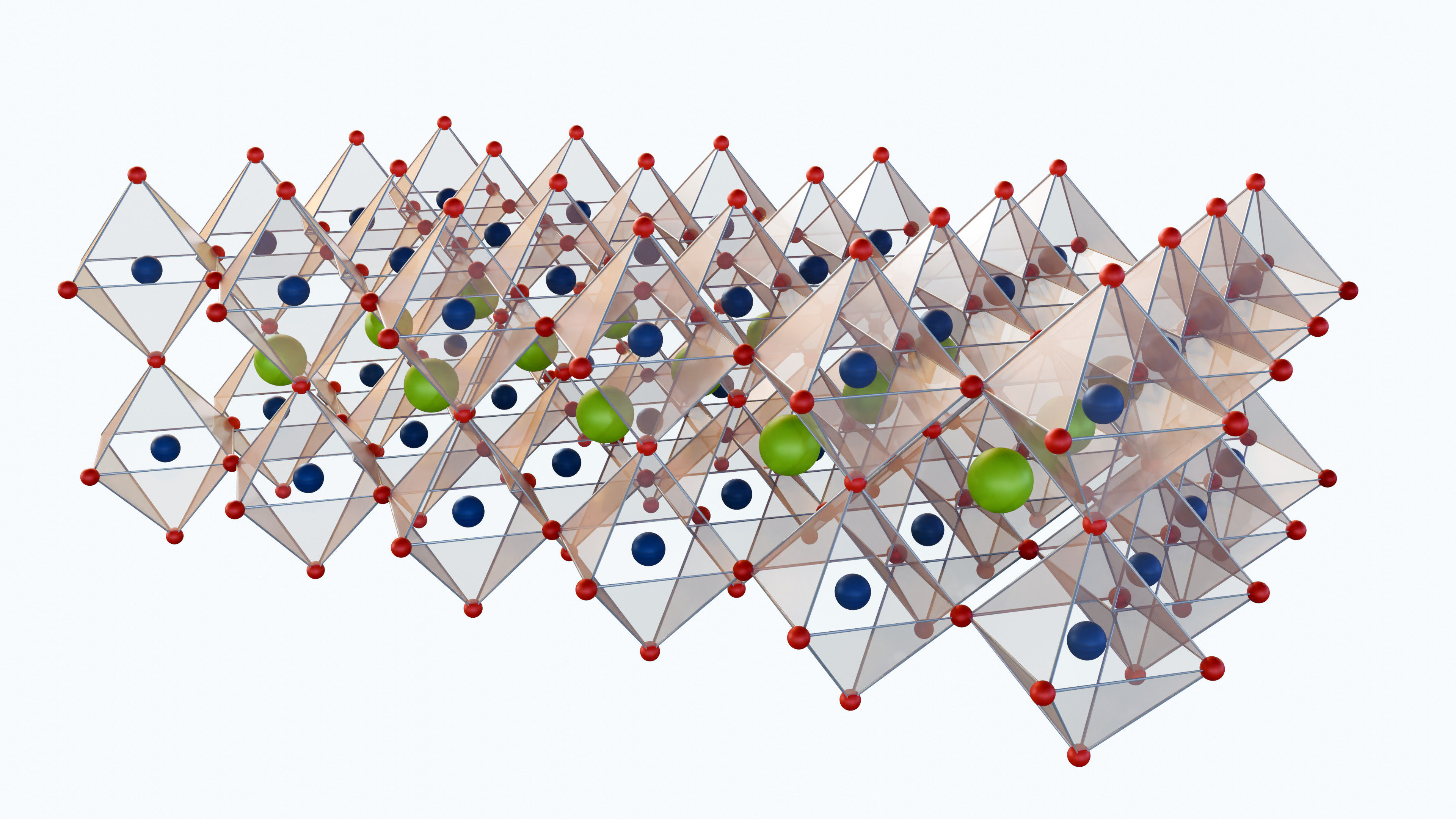

Perovskite Materials & Solutions

Machinery to Materials—Complete Perovskite Solutions

Vital delivers fully integrated perovskite solutions that reduce complexity, accelerate commercialization, and scale with confidence. From high-purity materials to modular equipment and closed-loop recycling, we support customers through every phase of development.

Key Value Propositions

- Integrated Total Solution: From materials to equipment and recycling—designed to reduce total cost of ownership and time-to-market.

- Materials Innovation: Engineered layers for enhanced adhesion, solubility, and long-term device stability in real-world environments.

- Accelerated Development: Fast-track progression from concept to lab to pilot scale production.

Why Choose Vital for Perovskite?

- Backed by advanced materials R&D, precision manufacturing, and global technical support.

- Connected materials, equipment, and recycling ensure greater operational resilience.

- Customized to your needs, scalable to your goals.

Ready to accelerate your perovskite development pipeline with Vital’s engineered materials and solutions? Contact our team to start the conversation.

Additional Featured Technologies

Low Melting Point Alloys

Precision Materials for Tooling, Molding, and Safety Applications

Vital Materials supplies low melting point alloys (LMPAs) engineered for applications requiring predictable phase change, dimensional stability, and safe handling. Also known as fusible alloys, these materials typically melt below 450°F (232°C) and are composed primarily of bismuth, with combinations of lead, tin, cadmium, or indium depending on formulation needs.

These alloys are trusted across industries for their ability to deliver precise performance in environments where heat activation, rapid forming, or safety release is essential.

Key Applications

- Workholding: Tooling for tube and pipe bending, aerospace support jigs

- Medical: Radiation therapy shielding and custom mold blocking

- Electronics: Heat fuses, thermal triggers, and low-temp soldering

Interested in learning more about bismuth materials or how to integrate low melting point alloys into your application? Contact us.

Bismuth

Environmentally Friendly Metal with Expanding Industrial Use

Bismuth is a non-toxic heavy metal used in applications ranging from cosmetics and pharmaceuticals to semiconductors and low-melt alloys. Known for its diamagnetism, low thermal conductivity, and high density, it is also gaining popularity as a lead-free alternative in soldering and radiation shielding.

Key Applications

- Pharmaceuticals: Anti-diarrheal and antibacterial compounds

- Metallurgy: Additive for machinability and low-melt alloys

- Electronics: Lead-free solders, thermal interface materials

Want to explore sourcing options or learn more about bismuth capabilities? Contact us.

Chalcogenide Glass (CHG)

Infrared-Transparent Materials for Optoelectronic Systems

Chalcogenide glass is a specialized material system containing sulfur, selenium, or tellurium, used in IR optical systems across defense, thermal imaging, and sensing. These materials offer wide transmission windows in the mid-IR range, high refractive indices, and resistance to thermal shock.

Key Applications

- Defense: Thermal weapon sights, night vision goggles

- Industrial: IR sensors and non-contact thermometers

- Automotive: Lidar and autonomous driving sensor windows

Interested in custom CHG formulations or optical blanks? Contact us.