Bonding Services

Thin Film Bonding Services

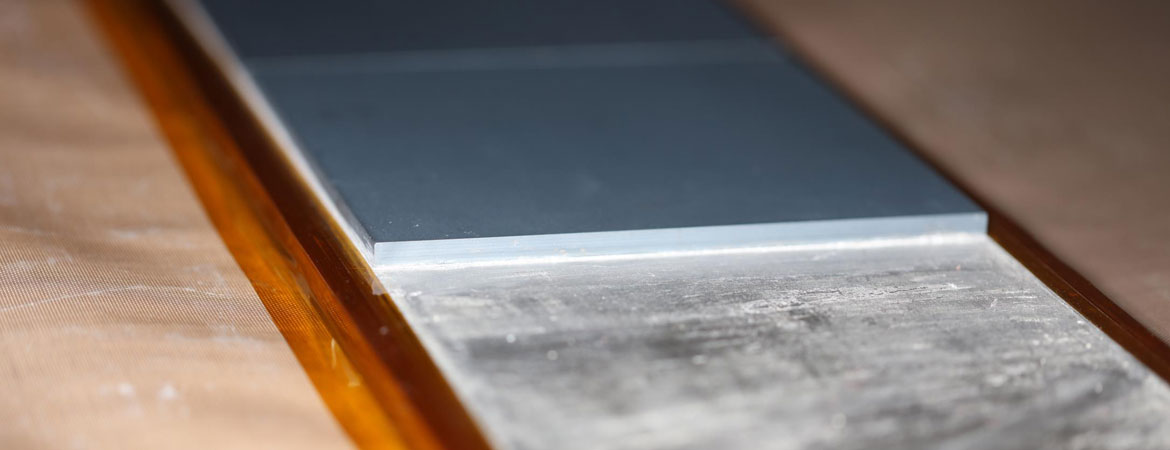

Depending on installed cathodes in your coating equipment, it is possible bonding is required. During the bonding process the target material is fixed on a carrier or cooling plate (also called a backing plate), which allows you to fix the sputtering target on your machine. A perfect bond will increase the cooling performance and will allow you to use higher power loads which increase your deposition rate.

We also provide suitable backing plates for your specific targets. Typical backing plate materials are Al, Cu, Mo, or Ti and are available up to 4000mm length.

Indium Bonding

Due to its very good thermal conductivity and its tensile properties Indium is the preferred solder for bonding sputtering targets.

The only limitation of this bond is the low melting point of indium which is at 156°C. That means that indium bonded targets are limited in power loads and need good cooling.

Diffusion Bonding

Our diffusion bonding services use a solid-state welding technique, capable of joining similar and dissimilar metals. It operates on the principle of solid-state diffusion, wherein the atoms of two solid, metallic surfaces intersperse themselves under pressure and heat.

Diffusion-bonded targets are mainly used in semiconductor-coating machines which allows the use of the targets under the highest power loads.

Diffusion bonding comes with higher expense and has the disadvantage that the backing plate can not be reused again.

Silver Epoxy Bonding

Silver epoxy bonding is often used for very brittle or temperature sensitive materials.

The epoxy is thermal and electrically conductive and is applied between the target material and the backing plate.

The big disadvantage of this bonding technique is that epoxy bonding has a relatively high thermal resistance which limits the power densities that the sputtering targets can use. This has direct influence on the deposition rates.

Due to its very good thermal conductivity and its tensile properties Indium is the preferred solder for bonding sputtering targets.

The only limitation of this bond is the low melting point of indium which is at 156°C. That means that indium bonded targets are limited in power loads and need good cooling.

Diffusion Bonding

Our diffusion bonding services use a solid-state welding technique, capable of joining similar and dissimilar metals. It operates on the principle of solid-state diffusion, wherein the atoms of two solid, metallic surfaces intersperse themselves under pressure and heat.

Diffusion-bonded targets are mainly used in semiconductor-coating machines which allows the use of the targets under the highest power loads.

Diffusion bonding comes with higher expense and has the disadvantage that the backing plate can not be reused again.

Silver Epoxy Bonding

Silver epoxy bonding is often used for very brittle or temperature sensitive materials.

The epoxy is thermal and electrically conductive and is applied between the target material and the backing plate.

The big disadvantage of this bonding technique is that epoxy bonding has a relatively high thermal resistance which limits the power densities that the sputtering targets can use. This has direct influence on the deposition rates.

Vital Materials provides a full range of the minor metal products. We can customize the purity, composition and forms for different industrial applications. Please contact us for more information.